The decision of whether to build your own CNC machine park or use the services of a subcontractor who will manufacture mechanical components on request is one of the most important operational choices in the industrial sector. It is a choice that affects not only the company’s finances, but also the time needed to implement new products, the availability of technology, operational flexibility, and design risk.

Not every manufacturing company needs to invest millions of dollars in modern machining centers and build technological facilities from scratch. On the other hand, it is not always worthwhile to outsource processes that are critical to quality, confidentiality, and precision.

In this article, we will analyze both approaches: investing in machines and outsourcing CNC machining, based on specific figures, real scenarios, and proven market practices.

The costs of investing in a CNC machine park – what do you really need to consider?

Buying a machine is just the beginning. Your own CNC machine park generates a number of additional costs that must be taken into account at the investment planning stage:

- Machine purchase: 3-axis VMC milling machines – from PLN 250,000 to PLN 650,000; 5-axis centers – from PLN 1 million to even PLN 2.5 million.

- CAD/CAM software: from PLN 60,000 to PLN 150,000, depending on the complexity of the machining and the manufacturer.

It is worth noting that CAM systems can be offered as perpetual licenses with an annual fee for updates or in a subscription model, where you pay annually. Price differences result from functionality, the number of machine axes, access to simulation and post-processors.

- Tooling: vices, probes, holders, tools – usually around 20% of the machine value.

- Hall adaptation: appropriate foundations, cooling, power supply – costs another 10–15% of the investment.

- Service and maintenance: on average 5–7% of the machine value per year.

- Technical staff: CNC operators, CAM programmers – indispensable for everyday work.

For an example 5-axis center, annual operating costs – excluding depreciation – can easily exceed PLN 400,000. This is a real challenge, especially if the machine is not working at full capacity.

Source: want.net – CNC Machine Cost Explained

Is 2,000 hours the break-even point?

In an industrial environment, it is generally accepted that approximately 2,000 machine hours per year is the approximate break-even point for an investment in a CNC machine tool. Where does this figure come from? It is roughly equivalent to the full utilization of a single machine in a single-shift system: 8 hours per day, 5 days per week, 50 weeks per year (with a reserve for service downtime and holidays).

Above this threshold, the investment begins to pay for itself – unit production costs decrease and capital efficiency increases. The longer the machine runs, the better the ROI (Return on Investment).

But in practice, this threshold can be difficult to achieve. Market data shows that the average utilization of CNC machines in single-shift plants is only 26% of available production time – significantly less than the required 2,000 hours. This is the result of underutilization, downtime, changeovers, and variable orders.

Conclusion? 2,000 hours is a realistic but ambitious goal that only pays off with regular, well-planned production volumes. In other cases, outsourcing should be considered as a solution with lower financial risk.

Source: https://www.machinemetrics.com/stateoftheindustry2022

When is it worth investing in your own CNC machine park?

Having your own CNC machine park is a solution that can bring tangible benefits. This is especially true when:

- You manufacture in large series – and are able to ensure a constant, intensive workload for your machine park. In this case, the unit cost drops significantly.

- You need very fast prototyping and frequent technological changes – although some experienced subcontractors offer such support, having machines on site shortens response times and gives you greater decision-making flexibility.

- You want to protect your technological know-how – especially in sectors such as aerospace, medicine, or defense. Although professional contractors sign non-disclosure agreements (NDAs), some companies prefer to keep sensitive data and processes exclusively within the organization.

- You want full control over the machining process – not only in terms of quality, but also in terms of optimizing the sequence of operations, maintaining uptime, and integrating with your own control systems.

While some of these needs can be met by external contractors, having your own machines gives your company decision-making independence, shorter response times, and the potential to optimize technology in real time.

What does CNC machining outsourcing offer?

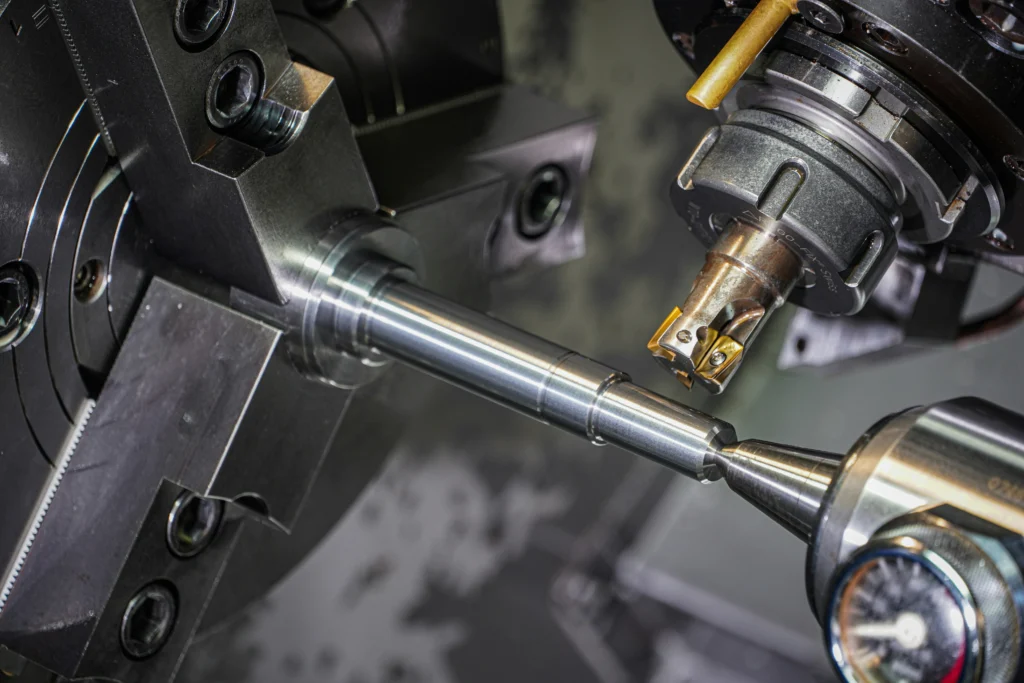

Outsourcing in the production of mechanical components is now much more than just ordering a part. Modern service companies are becoming technology partners, offering access to specialized machines without the need to build infrastructure from scratch.

Within a single partnership, you can obtain:

- Multiple technologies in one place – 5-axis milling, turning, EDM, anodizing, hardening, deburring, and much more.

- Engineering support – design optimization for easy and economical production (DFM – Design for Manufacturing). This is a process in which the component design is adapted to simplify its manufacture, reduce the number of operations, avoid difficult-to-maintain tolerances, and optimize the choice of materials.

- Systematic quality control – includes, among other things, precise measurements of details using coordinate measuring machines (CMM), which allow for accurate verification of dimensional compliance with technical documentation. In addition, there is full traceability of the production process, i.e., the ability to trace which materials were used and under what conditions each component was manufactured. Certificates of conformity and final test results can also be provided as part of the inspection.

Importantly, outsourcing also gives you access to the experience of a team that has been implementing projects for many industries for years. This experience translates into better technological advice, faster implementation, and a lower risk of errors during production.

When is outsourcing CNC machining advantageous?

Outsourcing CNC machining is worth considering when:

- Machine utilization does not exceed 2,000 hours per year,

- Projects are variable, irregular, or seasonal,

- You do not have the necessary personnel,

- You do not want to incur service, maintenance, and downtime costs,

- You need access to multiple technologies without capital investment.

More and more companies are using a mixed model – keeping basic production in-house and outsourcing more complex or occasional orders to external partners.

Summary

The decision on whether to develop your own machine park or outsource CNC machining is not just a matter of calculating the unit cost of production. It is a strategic choice that affects your operating model, cost structure, and project delivery speed.

Investing in machines is a good idea when you have a large, stable volume, need full control over the process, and have clearly defined technical competencies within the company. It’s a model that gives you independence, but it requires capital, planning, and high machine utilization to be profitable.

Outsourcing CNC machining, on the other hand, is a flexible, scalable and low-risk solution. It works well for companies that operate with variable demand, develop new products or need quick access to technology that is not cost-effective to implement permanently.